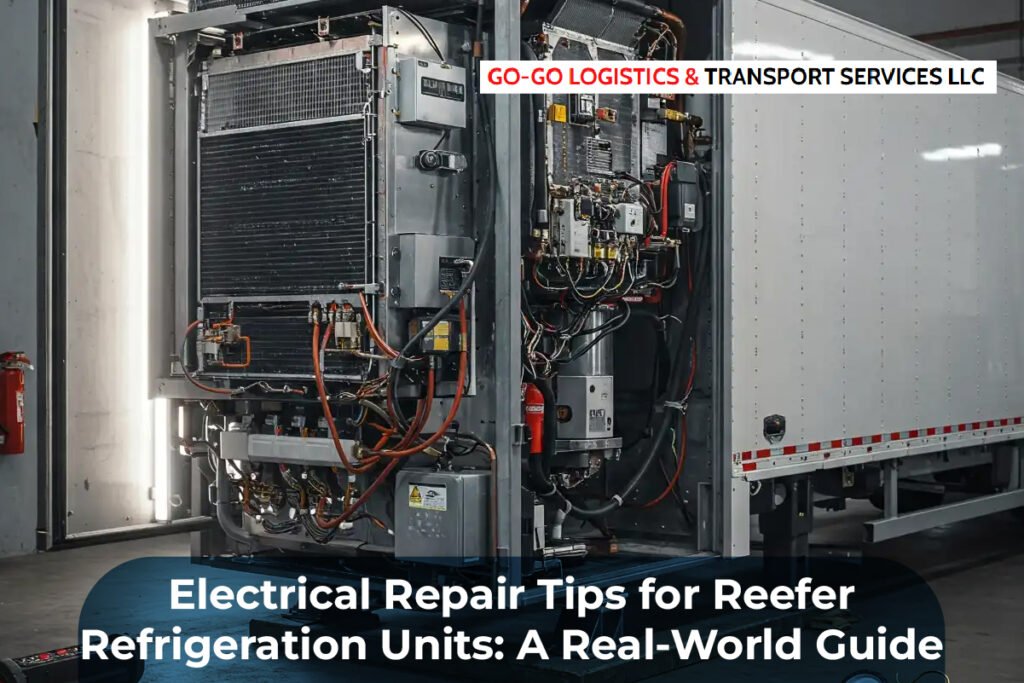

If you’ve ever been stuck on the side of the road with a trailer full of spoiled goods, you know reefer unit failure is no joke. These refrigeration systems are the unsung heroes of cold-chain logistics. When they go down, things heat up—literally. That’s why knowing a few essential electrical repair tips can save you time, stress, and money (okay, maybe not money in this blog, but you get the idea).

In this guide, I’ll walk you through practical advice from the real world of reefer repair—not the textbook stuff, but the “this-happens-in-the-yard-on-Monday” kind of insights. Whether you’re a solo operator, fleet manager, or someone trying to keep a cool head in hot situations, you’re in the right place.

1. Know Your Power Source (Before It Knows You)

Reefer units aren’t just plug-and-go. They operate on a combination of battery power, alternator support, and shore power when parked.

- Double-check the battery: Weak voltage is often the silent killer. If your unit’s struggling to kick on, grab a multimeter and check voltage at rest and under load.

- Don’t ignore the alternator: It’s not just the truck’s responsibility to power the reefer—it has to work with the alternator. If it’s underperforming, the reefer loses out.

A tech once told me, “Most reefer issues are just truck battery problems in disguise.” He wasn’t wrong.

2. Learn to Speak Blinky Light (AKA Alarms & Codes)

Your reefer speaks—just not in English. Every beep, blink, or fault code is its way of waving a flag.

- Read the fault codes: Every unit has a basic LED diagnostic or screen. Don’t just reset it—read it.

- Keep a quick-reference code sheet in the cab. Trust me, fumbling for it in the middle of the night isn’t fun.

When you ignore a code, you’re basically ghosting a cry for help. Don’t be that person.

3. Check Fuses Like You Mean It

Electrical gremlins often trace back to something small—like a fuse.

- Use a test light instead of visually checking. Looks can deceive.

- Look beyond just the main fuse box. Some reefer units have inline fuses hidden near control boxes or harness connections.

And don’t just replace fuses and call it fixed—ask why it blew. Was it moisture? A surge? A loose ground? The answer usually prevents round two.

4. Ground Yourself (And Your Unit)

Bad grounds are a technician’s worst enemy. They cause voltage drops, sensor misreads, and all kinds of erratic behavior.

- Inspect ground connections: Are they tight? Corroded? Painted over?

- Use a voltmeter to measure voltage drop between ground points and battery negative. Anything over 0.5V? That’s a problem.

Think of grounds like gossip—if they’re weak, everything gets misunderstood.

5. Stay Sharp on Sensor Health

Sensors are everywhere in a reefer: temp probes, pressure transducers, ambient sensors.

- Calibrate or replace faulty temp sensors regularly. A sensor that reads 4°F off can cause your entire system to overreact—or not react at all.

- Watch for erratic readings: If a sensor’s bouncing around wildly, it may have frayed wiring or be shorting internally.

You wouldn’t drive blindfolded. Don’t let your reefer try.

6. Harness Checks: Tug, Twist, Test

Electrical harnesses go through a warzone—heat, vibration, moisture, you name it.

- Inspect harnesses during scheduled service: Look for frays, pinches, or signs of rubbing against sharp metal.

- Twist-and-tug test connectors: A loose pin now becomes a full-blown shutdown later.

I’ve seen trailers sidelined for what ended up being a $2 terminal pin.

7. Know When to Call It (And Who to Call)

Let’s be real—sometimes it’s smarter to call a tech than risk frying a control board.

- If you’re seeing intermittent electrical issues and nothing obvious, stop and document the symptoms.

- Keep contact info for certified reefer repair techs on hand (in your glovebox, not just your phone).

Even seasoned mechanics need backup. It’s not a weakness—it’s wisdom.

8. Preventive Maintenance Isn’t Optional—It’s Insurance

The best repairs? The ones you don’t need. And that’s where a solid preventive electrical checklist saves the day.

- Regularly inspect all terminals, connectors, and relays for signs of heat or wear.

- Test your reefer’s start-up and shut-down cycle weekly, especially in off-peak seasons.

Make it routine, and you’ll avoid the 3 a.m. breakdown call that starts with “It was working fine yesterday…”

Frequently Asked Questions (FAQs)

What are common electrical issues in reefer units?

Battery voltage drops, blown fuses, bad grounds, and sensor malfunctions top the list. Most are preventable with routine checks.

How often should I check my reefer’s electrical system?

A quick visual and power test weekly, and a full inspection monthly is a good rule of thumb.

Is it safe to DIY reefer electrical repairs?

Some minor checks and repairs (fuses, battery terminals, harness inspections) are safe. But anything involving control boards or major rewiring? Call a pro.

Why does my reefer keep throwing error codes?

Could be sensors, voltage inconsistencies, or even software glitches. Don’t just clear them—read and understand them.

Final Reflections

When it comes to reefer refrigeration units, ignoring small electrical problems is like ignoring a leaky roof—it’ll cost you more later. Hopefully, these real-world tips give you a stronger grip on keeping your unit cold, your cargo safe, and your day a little less chaotic.

And hey—if you’re looking for professionals who actually get the logistics grind, Gogo Logistics Transport & LLC is the kind of name you want in your corner. From experience-backed service to real road wisdom, they know what keeps fleets rolling.