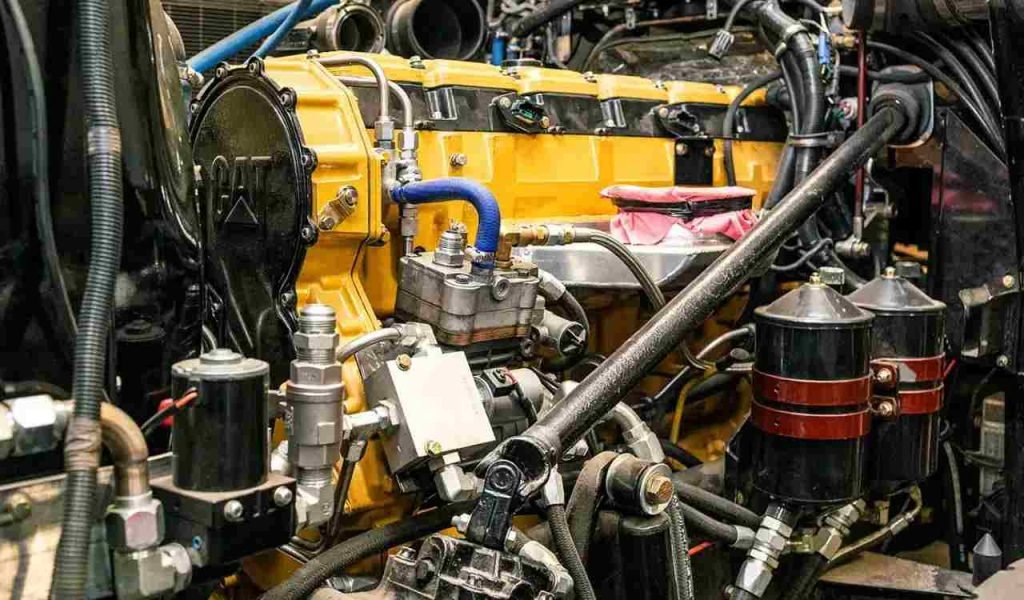

Knowing whether your truck engine needs a complete rebuild can be challenging, but it’s crucial for maintaining performance and avoiding costly repairs. Engines are complex machines, and various signs can indicate underlying issues that may require a rebuild. Common symptoms include persistent knocking or tapping noises, excessive smoke from the exhaust, a noticeable drop in power, or frequent stalling. Additionally, if your engine is consuming excessive amounts of oil or coolant, it might be a sign of internal damage. Monitoring these symptoms and seeking professional diagnostics can help determine if a rebuild is necessary. In this guide and along with the help of Go-go Logistics & Transport, we will explore how to identify these signs and what steps to take to address potential engine issues effectively.

Regular maintenance and prompt attention to engine problems are key to keeping your truck running smoothly and efficiently. Engine repair services play a crucial role in addressing issues before they escalate into major problems that might require costly overhauls. Timely repairs can prevent minor issues from becoming significant and ensure the longevity of your engine. Keeping a close eye on engine performance and addressing any unusual signs promptly will extend the life of your truck and ensure reliable operation. Regular inspections by a professional can help catch potential issues early and maintain your engine in optimal condition.

Signs Your Engine Might Need a Rebuild

Identifying signs that your truck engine needs a rebuild involves recognizing symptoms of serious internal damage. Common indicators include persistent knocking or tapping sounds that suggest worn or damaged engine components. If you notice excessive exhaust smoke, it may indicate burning oil or coolant, both of which can signal severe engine issues. Transmission troubles, such as slipping gears or delayed shifting, can also affect engine performance and may point to underlying problems. A noticeable drop in power or frequent stalling can further indicate significant internal problems. Monitoring these symptoms and comparing them with regular performance checks can help you determine whether a rebuild is necessary. Addressing these issues early can prevent further damage and potentially more costly repairs down the line.

Common Symptoms Indicating Engine Trouble

Engine trouble often manifests through specific symptoms that can signal the need for a rebuild. These include unusual noises like knocking or pinging, which may indicate problems with internal engine parts. Excessive exhaust smoke, whether blue, white, or black, suggests that the engine is burning oil, coolant, or fuel improperly. A significant drop in engine power, where the truck struggles to accelerate or maintain speed, can be a sign of internal damage. Frequent stalling or misfires can also indicate severe engine issues. Recognizing these symptoms early and consulting a professional for timely truck engine repair can prevent further damage and save money in the long run by avoiding more costly repairs.

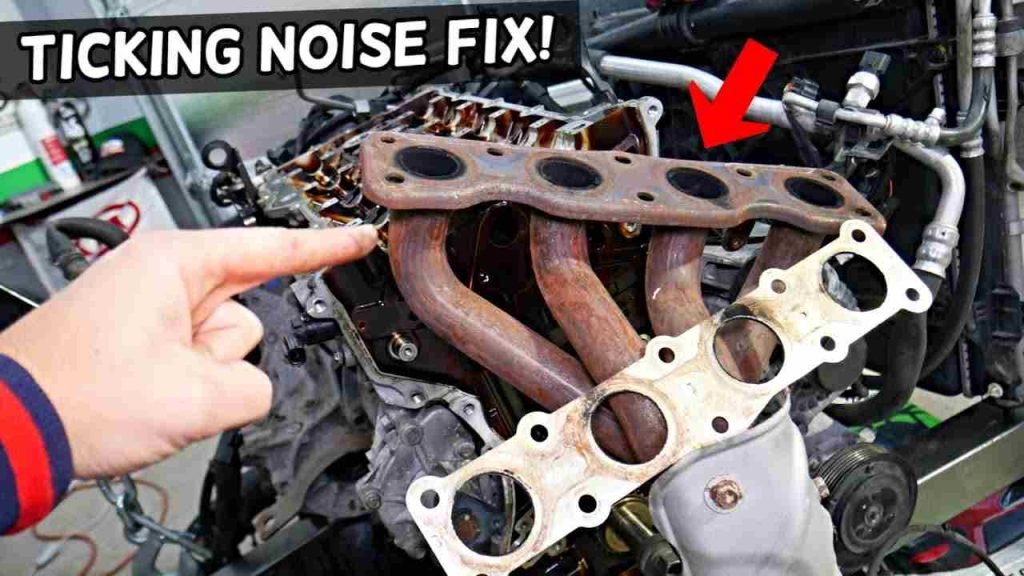

Understanding Engine Knocking and Tapping Noises

Engine knocking and tapping noises are key indicators of potential internal damage and may suggest the need for a rebuild. Knocking noises, often described as a metallic sound, can be caused by issues such as worn bearings, damaged pistons, or failing connecting rods. Tapping sounds, on the other hand, might be due to worn valve lifters or rocker arms. These noises indicate that critical engine components are not functioning correctly, which can lead to further damage if left unchecked. If your truck engine makes a knocking noise, it’s crucial to seek professional diagnosis and repair services immediately. Regular maintenance and immediate attention to these sounds can help identify the cause and determine whether a rebuild is necessary to restore optimal engine performance.

Excessive Exhaust Smoke: What It Means

Excessive exhaust smoke can be a crucial sign that your truck engine may need a rebuild. Different colors of smoke can indicate specific issues: blue smoke often means the engine is burning oil, possibly due to worn piston rings or valve seals. White smoke may suggest coolant is leaking into the combustion chamber, which can be a sign of a blown head gasket or a cracked engine block. Black smoke indicates an overly rich fuel mixture, which could point to problems with the fuel injectors or carburetor. Addressing the cause of excessive smoke promptly is essential to prevent further engine damage and determine if a rebuild is needed.

How to Identify a Drop in Engine Power

A noticeable drop in engine power can be a significant symptom that your truck engine might need a rebuild. This issue can manifest as difficulty accelerating, reduced top speed, or a general lack of responsiveness. A drop in power can be caused by various internal problems, such as worn-out pistons, damaged cylinder walls, or failing valves. Other contributing factors might include clogged air filters, malfunctioning fuel injectors, or issues with the turbocharger. Monitoring engine performance regularly and addressing any noticeable changes can help in diagnosing the problem. Professional diagnostics can confirm whether a rebuild is necessary to restore your engine’s power and efficiency.

The Impact of Frequent Engine Stalling

Frequent engine stalling can be a clear indicator that your truck engine may require a rebuild. Stalling occurs when the engine unexpectedly stops running, which can be caused by issues such as worn or damaged internal components, fuel delivery problems, or ignition system failures. Persistent stalling may also result from problems with the engine’s timing or compression. If the engine frequently stalls, it is crucial to investigate the underlying cause and determine whether a rebuild is needed to address the issue. Regular inspections and addressing stalling issues promptly can prevent further damage and ensure reliable engine performance.

Oil and Coolant Consumption: What’s Normal?

Understanding normal oil and coolant consumption is essential in determining if your truck engine needs a rebuild. Engines naturally consume a small amount of oil over time, but excessive oil consumption can indicate internal problems such as worn piston rings or valve seals. Similarly, a small amount of coolant loss is normal, but significant or rapid coolant consumption could signal a leak or a problem with the head gasket or engine block. Monitoring your truck’s oil and coolant levels regularly and comparing them to manufacturer recommendations can help identify abnormal consumption rates. Addressing these issues promptly can prevent further damage and determine if a rebuild is necessary.

When to Seek Professional Engine Diagnostics

Seeking professional engine diagnostics is crucial when you suspect your truck engine may need a rebuild. If you notice symptoms such as unusual noises, reduced power, excessive smoke, or frequent stalling, a professional can conduct a thorough inspection to diagnose the issue accurately. Diagnostic tools and techniques, including compression tests, leak-down tests, and electronic scans, can help identify internal problems that may not be visible during a routine check. A qualified mechanic can provide a detailed assessment and recommend whether a rebuild or other repairs are necessary. Early and accurate diagnosis helps prevent further damage and ensures effective resolution of engine issues.

The Cost of Engine Rebuild vs. Replacement

Evaluating the cost of an engine rebuild versus replacement is essential for making an informed decision about your truck’s repair needs. An engine rebuild involves disassembling the engine, repairing or replacing damaged components, and reassembling it, which can be labor-intensive and expensive. However, it may be more cost-effective than a full engine replacement, especially if the existing engine has substantial life remaining. Engine replacement, on the other hand, involves installing a new or remanufactured engine, which can be a significant investment but offers a fresh start. Comparing the costs, benefits, and potential longevity of each option can help you choose the best solution for your budget and vehicle.

Preventive Maintenance to Avoid Engine Rebuilds

Preventive maintenance is key to avoiding the need for an engine rebuild and extending the life of your truck’s engine. Regular maintenance tasks include routine oil changes, timely replacement of filters, and monitoring fluid levels. Keeping up with scheduled maintenance and addressing minor issues before they escalate can prevent major engine problems. Additionally, performing regular inspections and addressing signs of wear or malfunction early can help avoid costly repairs. By following the manufacturer’s recommended maintenance schedule and seeking professional help when needed, you can reduce the risk of severe engine damage and extend the engine’s overall lifespan.

How Regular Inspections Can Save You Money

Regular inspections play a crucial role in saving money on engine repairs and avoiding costly rebuilds. By having your truck engine inspected routinely, you can catch potential issues early before they develop into more significant problems. Regular checks can identify wear and tear, fluid leaks, or performance drops that might indicate underlying issues. Addressing these problems early can prevent them from worsening and requiring expensive repairs. Investing in regular inspections helps maintain engine health, improves performance, and ultimately reduces the likelihood of unexpected breakdowns or major repairs, providing long-term savings and reliability for your truck.

Conclusion

Determining whether your truck engine needs a complete rebuild involves recognizing various signs of serious internal damage. From persistent knocking noises and excessive exhaust smoke to a noticeable drop in power and frequent stalling, these symptoms can indicate significant engine issues. Understanding these warning signs and seeking professional diagnostics are crucial steps in deciding whether a rebuild or other repairs are necessary. Regular maintenance and prompt attention to engine problems can help prevent severe damage and costly repairs. By staying vigilant and addressing engine issues early, you can ensure your truck remains reliable and performs optimally, extending its lifespan and avoiding major disruptions to your operations.

FAQs

What are common signs that my truck engine needs a rebuild?

Common signs include persistent knocking noises, excessive exhaust smoke, a noticeable drop in power, and frequent stalling. Excessive oil or coolant consumption can also indicate internal damage.

2. How can I diagnose if my truck engine requires a rebuild?

Professional diagnostics are essential. Mechanics use tools and tests to check for internal damage, such as compression tests and visual inspections, to determine if a rebuild is necessary.

3. What factors contribute to needing an engine rebuild?

Factors include severe wear and tear, neglecting maintenance, overheating, and major internal damage. Frequent and severe issues with the engine’s performance may also necessitate a rebuild.

4. Can regular maintenance prevent the need for an engine rebuild?

Yes, regular maintenance can help prevent severe engine damage. Routine checks, timely oil changes, and addressing minor issues promptly can extend engine life and avoid costly rebuilds.

5. What is the cost implication of an engine rebuild compared to repairs?

An engine rebuild is typically more expensive than minor repairs but can be more cost-effective than replacing the engine. The cost varies based on the extent of damage and the parts needed.