Ever wonder what keeps those big rigs rolling smoothly down the highway? Well, it’s not just the engine—it’s the unsung heroes, the belts and hoses! These seemingly small components play a huge role in keeping truck engines running like well-oiled machines. But here’s the catch: they need regular TLC, too. In this blog post, Go-go Logistics & Transport Services LLC dives to why timely replacement of belts and hoses is absolutely crucial for the health, safety, and efficiency of truck engines. So buckle up (pun intended), and let’s explore the importance of giving these vital parts the attention they deserve!

Understanding Belts and Hoses

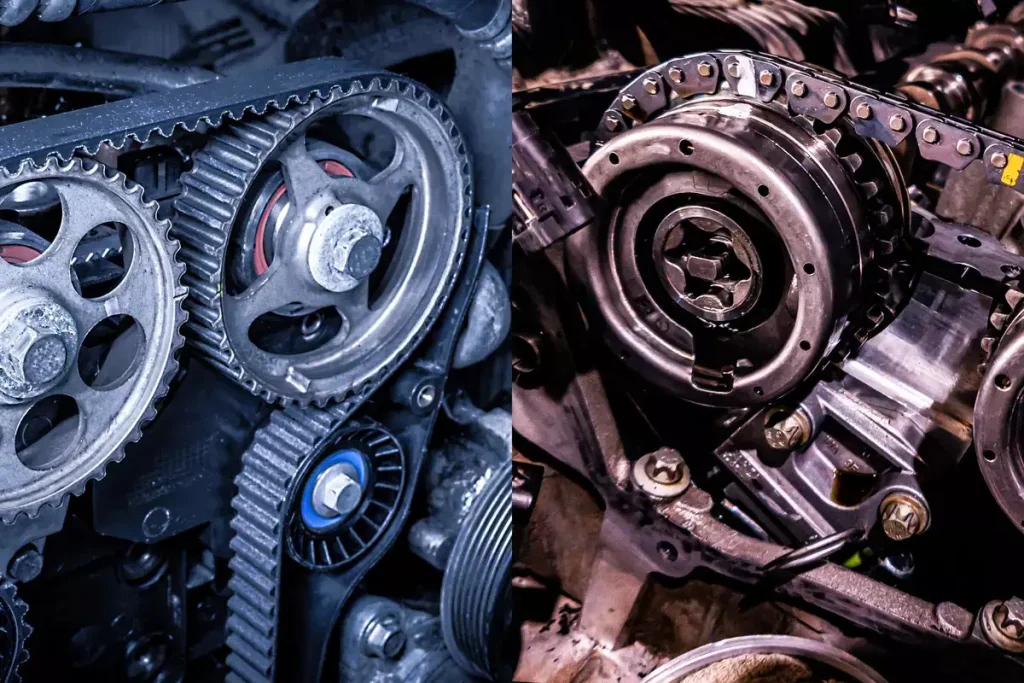

Before delving into the significance of timely replacement, it’s crucial to understand the functions of belts and hoses within a truck engine. Belts in truck engines are primarily responsible for transferring power from the crankshaft to various engine accessories such as the alternator, water pump, and air conditioning compressor. Meanwhile, hoses facilitate the circulation of vital fluids like coolant and oil throughout the engine, ensuring optimal temperature regulation and lubrication.

Belts and hoses are essential components within truck engines, often overlooked but critical for optimal performance. Belts transmit power from the crankshaft to various engine accessories, such as the alternator and water pump, ensuring their smooth operation. Meanwhile, hoses facilitate the circulation of vital fluids like coolant and oil, maintaining engine temperature and lubrication. Together, these components form a dynamic network that keeps the engine running efficiently. Understanding their roles highlights the importance of regular inspection and timely replacement to prevent unexpected failures and costly repairs, ensuring the longevity and reliability of truck engines.

The Consequences of Neglect

Neglecting the maintenance of belts and hoses can have dire consequences for both the truck and its operator. Over time, belts are subject to wear and tear, leading to cracks, fraying, and eventual failure. A snapped belt can result in a sudden loss of power steering, electrical charging, or even engine cooling, potentially causing catastrophic engine damage or accidents on the road. Similarly, deteriorating hoses are prone to leaks, which can result in coolant loss, overheating, and engine seizures if left unchecked.

Neglecting the maintenance of belts and hoses in truck engines can lead to dire consequences. A snapped belt or leaking hose can cause sudden engine failure, resulting in costly repairs and potential accidents on the road. Moreover, prolonged neglect can lead to more extensive damage, impacting not only the engine but also other critical components of the truck and trailer. Recognizing the severity of these consequences underscores the importance of regular inspection and prompt replacement of belts and hoses. Partnering with a reputable truck and trailer repair service ensures proactive maintenance, minimizing downtime and preserving the integrity of the entire vehicle system.

Financial Implications

Beyond the immediate safety concerns, failing to replace belts and hoses in a timely manner can incur significant financial costs. A broken belt or hose failure often leads to expensive repairs, including engine rebuilds or replacements. Moreover, the downtime associated with such repairs can translate into lost revenue for trucking companies and additional expenses for independent operators. By contrast, the relatively minor cost of preventive maintenance pales in comparison to the potential expenses arising from neglect.

The financial implications of neglecting belt and hose maintenance in truck engines can be substantial. A broken belt or leaking hose can result in unexpected repair costs, including engine damage that may require extensive repairs or even a full engine replacement. Additionally, the downtime associated with these repairs can lead to lost revenue for trucking companies and independent operators, further exacerbating the financial impact.

Partnering with a reliable truck engine repair service can mitigate these financial risks. By conducting regular inspections and proactive maintenance, skilled technicians can identify potential issues early on, minimizing the likelihood of costly breakdowns. Moreover, timely replacement of belts and hoses ensures uninterrupted operation, reducing downtime and preserving the financial stability of trucking operations in the long run.

Preventive Maintenance Saves Money and Time

Embracing a proactive approach to maintenance by adhering to manufacturer-recommended replacement intervals can save truck owners considerable time and money in the long run. Regular inspections conducted by trained technicians can identify signs of wear or damage before they escalate into major issues. Prompt replacement of belts and hoses ensures uninterrupted operation, minimizes the risk of breakdowns, and extends the service life of the engine. Additionally, investing in high-quality belts and hoses from reputable manufacturers can offer added reliability and durability, further reducing the likelihood of premature failure.

Embracing preventive maintenance practices for belts and hoses in truck engines can yield significant savings in both time and money. Regular inspections and timely replacements help identify potential issues before they escalate into costly breakdowns, minimizing the need for expensive repairs or emergency servicing. By investing in preventive maintenance, truck owners can avoid unexpected downtime, ensuring their vehicles remain operational and productive. Moreover, proactive upkeep reduces the risk of major failures on the road, promoting safer driving conditions and protecting against potential liabilities. Ultimately, prioritizing preventive maintenance not only saves money but also maximizes the efficiency and reliability of truck operations.

Investing in preventive maintenance not only saves money and time but also lays the groundwork for finding affordable truck engine repair services in Lanham. By adhering to regular maintenance schedules and promptly addressing any issues with belts and hoses, truck owners can minimize the likelihood of costly breakdowns. When seeking repair services, look for providers in Lanham who offer competitive pricing without compromising on quality. Additionally, prioritize companies with a track record of expertise in truck engine repair and a commitment to preventive maintenance practices.

Environmental Considerations

Beyond the financial and safety implications, there are environmental considerations associated with neglected belt and hose maintenance. Leaking hoses can result in the release of harmful fluids such as coolant or oil into the environment, contaminating soil and water sources. Moreover, inefficient engine performance due to worn belts can lead to increased fuel consumption and emissions, contributing to air pollution and climate change. By maintaining belts and hoses in optimal condition, truck operators can minimize their ecological footprint and contribute to sustainability efforts within the transportation industry.

- Neglected belts and hoses can lead to fluid leaks, releasing harmful substances like coolant and oil into the environment.

- Inefficient engine performance due to worn belts increases fuel consumption and emissions, contributing to air pollution and climate change.

- Regular maintenance reduces the likelihood of leaks and ensures optimal engine efficiency, minimizing environmental impact.

- Preventive measures help preserve natural resources by extending the lifespan of engine components and reducing the need for replacements.

- By prioritizing environmental considerations in maintenance practices, truck operators can contribute to sustainability efforts and minimize their ecological footprint in the transportation industry.

Compliance and Regulatory Standards

For commercial trucking operations, adherence to maintenance schedules is not merely a matter of good practice but a legal requirement. Regulatory bodies such as the Department of Transportation (DOT) enforce stringent safety standards to ensure the reliability and roadworthiness of commercial vehicles. Failure to comply with these standards can result in fines, penalties, or even the suspension of operating licenses. Timely replacement of belts and hoses is, therefore, a crucial aspect of regulatory compliance, safeguarding both the reputation and legal standing of trucking companies and independent operators.

Adhering to compliance and regulatory standards is crucial for truck operators to ensure safety and legality. Regulatory bodies, like the Department of Transportation (DOT), enforce strict guidelines regarding vehicle maintenance, including belts and hoses. Failure to comply can result in fines or license suspensions. Partnering with a reputable truck electrical repair service ensures adherence to these standards. Experienced technicians can not only address electrical issues but also ensure overall compliance with regulatory requirements, safeguarding the reputation and legal standing of trucking operations.

Educating Operators and Technicians

Effective maintenance strategies rely on the collaboration between truck operators and skilled technicians. Educating operators about the importance of regular inspections and maintenance routines empowers them to identify early warning signs and address issues promptly. Likewise, providing ongoing training for technicians ensures that they possess the expertise and resources necessary to perform thorough inspections and replacements. By fostering a culture of preventive maintenance, trucking companies can mitigate risks, enhance safety, and optimize the performance of their fleets.

Educating operators and technicians is essential for effective maintenance practices. Operators should be trained to recognize signs of belt and hose wear, promoting early detection of potential issues. Additionally, ongoing training for technicians ensures they possess the expertise to perform thorough inspections and replacements. By fostering a culture of continuous learning and collaboration, trucking companies can empower their teams to uphold the highest standards of maintenance, enhancing safety and efficiency on the road.

FAQs

Why is it important to replace the timing belt?

A timing belt is vital for your vehicle to function. Without a maintained timing belt, the camshaft and crankshaft can become mistimed, causing you to be stranded on the road in the best-case scenario and left with a damaged engine in the worst case.

What is the importance of replacing drive belt?

By the time most cars reach 90K miles, it’s recommended to replace the serpentine belt (regardless of the appearance) to reduce the chances of it breaking, explains AutoZone. A broken serpentine belt can be dangerous while driving and could cause serious damage to your engine.

How does a timing belt affect performance?

A worn-out timing belt has a significant impact on your car’s revolutions per minute (RPMs), which shows how hard the engine is working. A timing belt missing some teeth or snapping completely can cause the RPM to act inconsistently.

Does timing belt affect engine performance?

The timing belt synchronises the movement of the pistons and engine valves. Wear and tear of the timing belt can affect this process, also affecting engine performance. In this case, you’re likely to notice that your car struggles to switch gears or accelerate.

How important is engine timing?

Setting the correct ignition timing is crucial in the performance of an engine. Sparks occurring too soon or too late in the engine cycle are often responsible for excessive vibrations and even engine damage. The ignition timing affects many variables including engine longevity, fuel economy, and engine power.

Conclusion

In conclusion, the significance of timely belt and hose replacement in truck engines cannot be overstated. These seemingly minor components play a vital role in maintaining the reliability, safety, and efficiency of truck operations. Neglecting their maintenance can lead to costly repairs, downtime, and safety hazards. By prioritizing preventive maintenance and adhering to manufacturer-recommended replacement intervals, truck owners and operators can ensure smoother operations, minimize risks, and uphold regulatory compliance. So, let’s keep those belts tight and hoses leak-free, because when it comes to truck engines, a little maintenance goes a long way in keeping things running smoothly on the road.